Factory-Direct Custom Fastener Parts

Lower MOQ

100pcs/model

Direct Selling

Competitive Price Factory

OEM/ODM

Customization Service

Warranty

1 Year/ 30,000kms

30-45 Days

Delivery Time

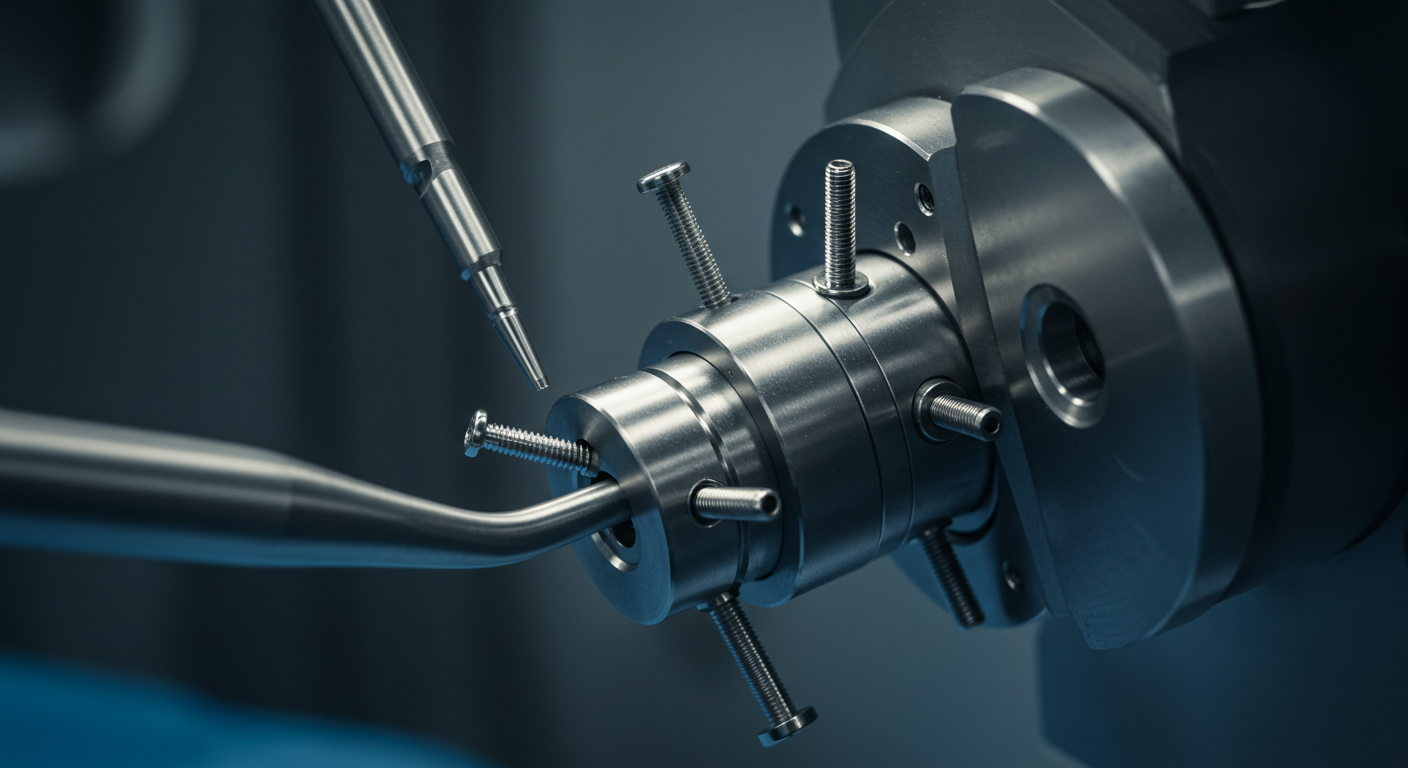

Pioneering custom Fastener Parts for the future of industry

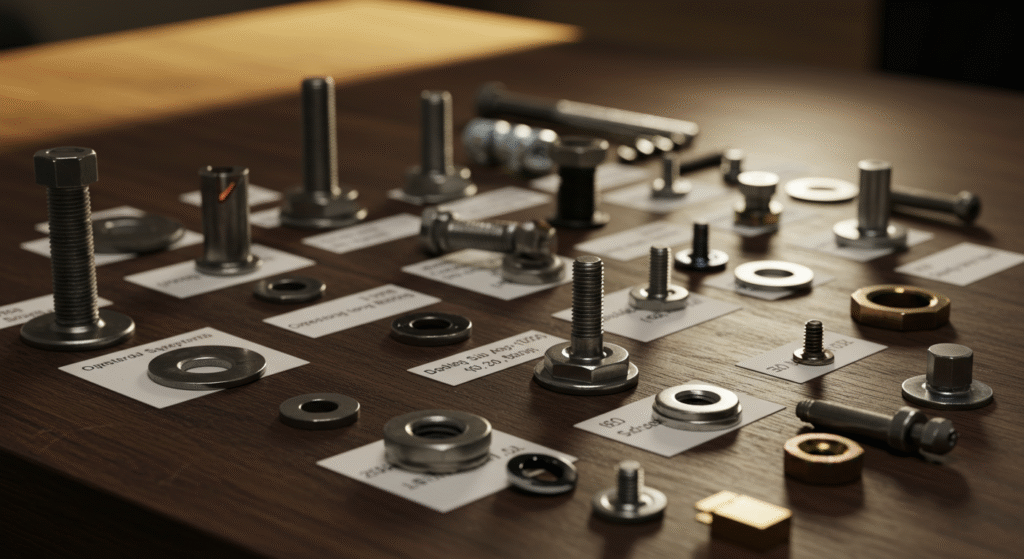

Screws

Bolts

Nuts

Washers

Rivet

Aluminum Rod Adapter

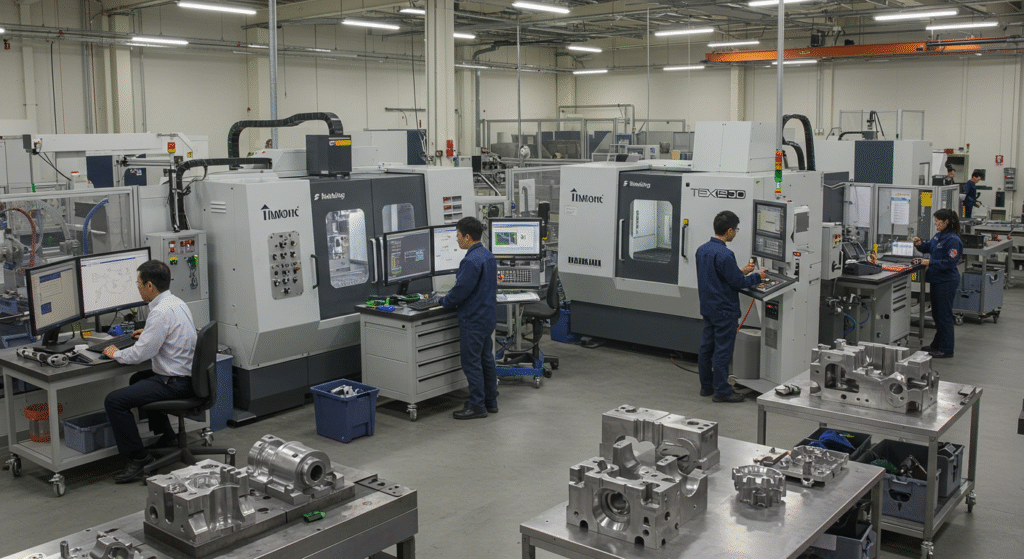

Precision Metalworks Since 1993 ISO-certified manufacturing for your most demanding applications.

This Is How We Stand Out

Affordable, adaptable, and precise—our custom metal parts are built for your unique needs

1. Premium Materials for Reliability

2.Precision Manufacturing

3.Suitable Price

4.Strict Quality Assurance

We use high-grade metals such as carbon steel, stainless steel, aluminum, and alloys, ensuring strength, corrosion resistance, and long service life in demanding environments.

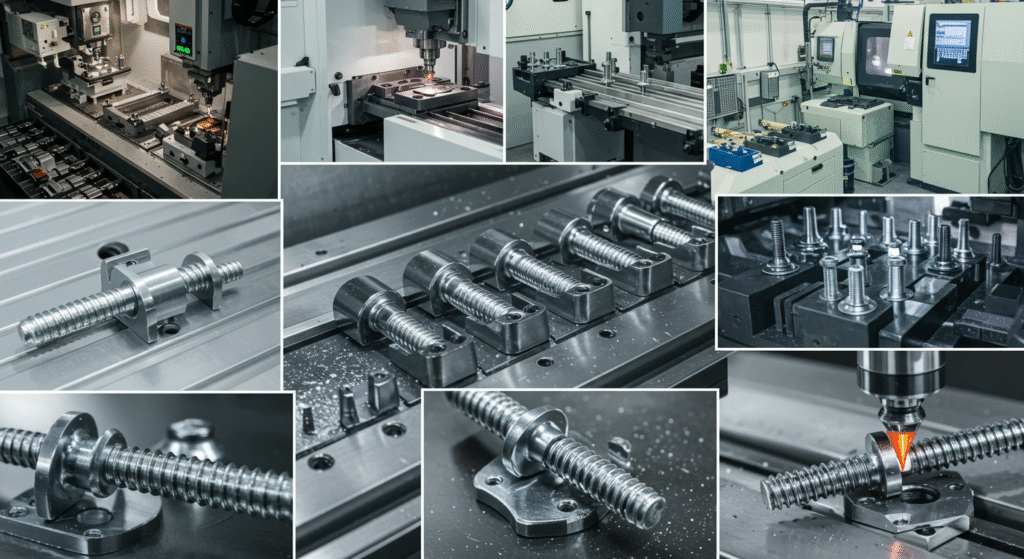

Our fasteners are produced with advanced stamping, CNC, and forging technologies, delivering tight tolerances, consistent dimensions, and reliable performance across every batch.

We offering high-quality fasteners at a cost-effective rate. Customers receive reliable, durable products without paying a premium, ensuring excellent value for every order.

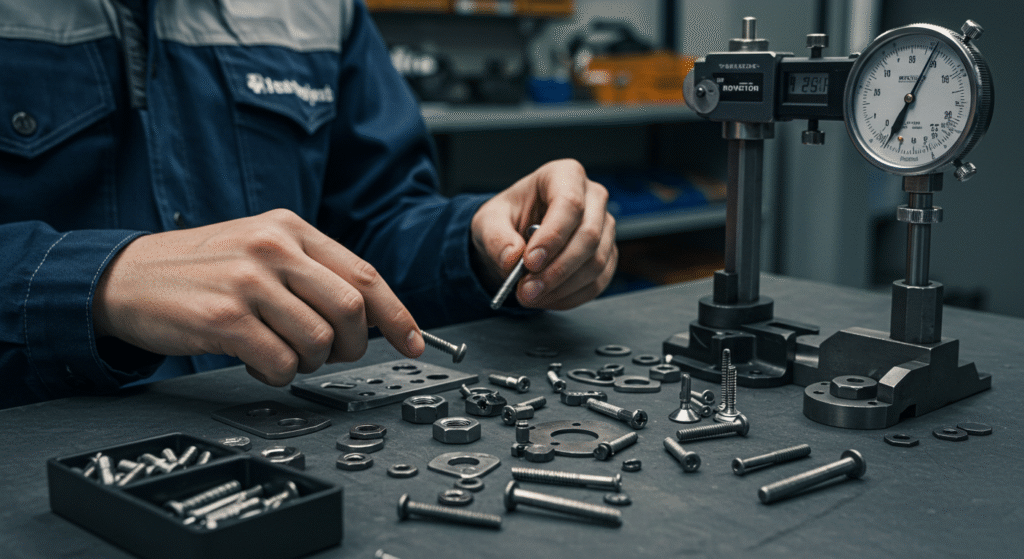

Every fastener undergoes comprehensive inspection—from raw material testing to dimensional checks and surface treatment verification—ensuring defect-free products and global compliance.

Guiding You Every Step of the Way

Requirement Analysis

Material Selection

Engineering & Design

Tooling & Mold Preparation

Sample & Prototyping

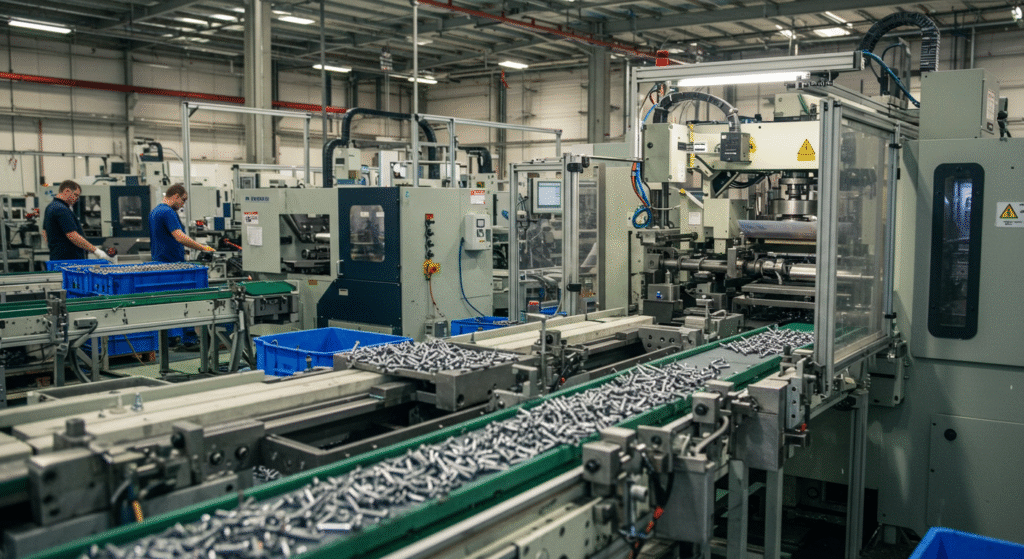

Mass Production

Main Processing Technology

Quality Inspection

Packaging & Labeling

Delivery & Logistics

Guiding You Every Step of the Way

Real-World Usage

Automotive & Transportation

Covers vehicles and mobility systems such as cars, trucks, trains, ships, and aircraft. In this field, fasteners are critical for ensuring safety, durability, and reliable performance under constant vibration, load, and environmental stress.

Machinery & Equipment Manufacturing

Involves the production of industrial machines, construction equipment, agricultural machinery, and various mechanical systems. Fasteners play a vital role in assembling and securing components, ensuring stability, precision, and long service life under demanding working conditions.

Construction & Infrastructure

Refers to buildings, bridges, tunnels, and large-scale structural projects. Fasteners are essential for connecting steel structures, supporting heavy loads, and ensuring long-term stability and safety in demanding environments.

Energy & Power Industry

Covers sectors such as wind power, solar energy, oil & gas, and power generation. Fasteners are crucial for assembling turbines, pipelines, and pressure vessels, ensuring reliability, safety, and consistent performance under extreme conditions.

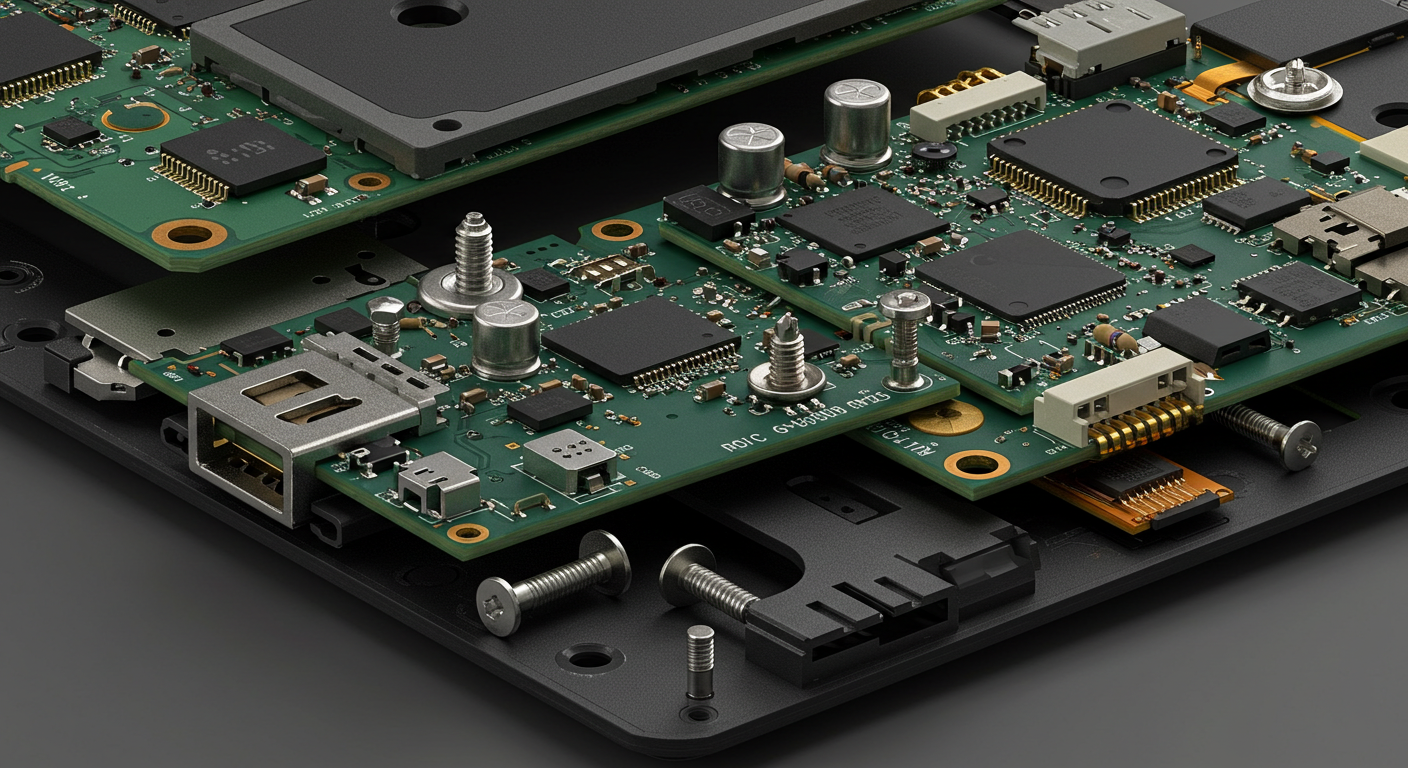

Home Appliances & Consumer Electronics

Metal forging is often chosen when parts must be extremely strong, reliable, and able to withstand heavy wear and impact. This process is widely applied in cars, airplanes, energy equipment, industrial machinery, and defense hardware — especially for parts that face constant pressure or harsh working conditions.

Medical & Special Industries

Metal forging is often chosen when parts must be extremely strong, reliable, and able to withstand heavy wear and impact. This process is widely applied in cars, airplanes, energy equipment, industrial machinery, and defense hardware — especially for parts that face constant pressure or harsh working conditions.

Quality Control

We apply strict quality control to every order, guaranteeing products that match your specifications and meet all standards.

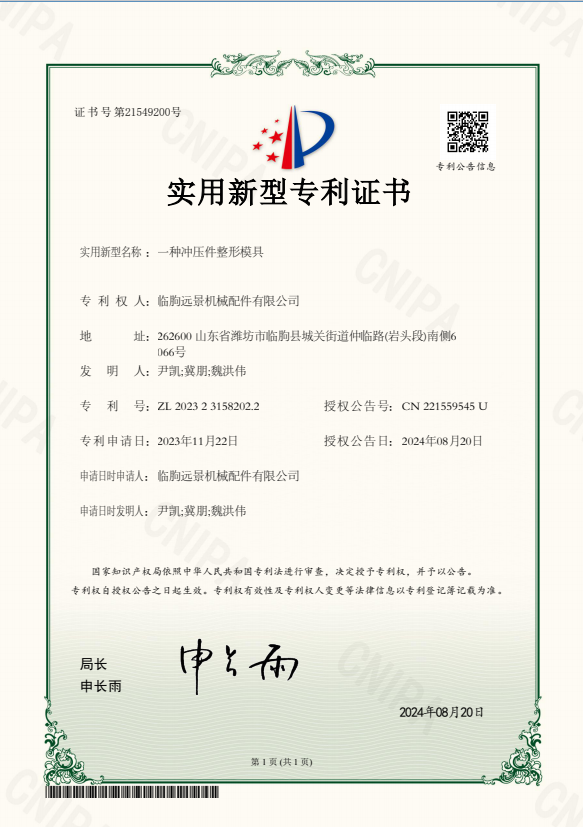

- ISO 9001, ISO 14001, Responsible Care® Certified

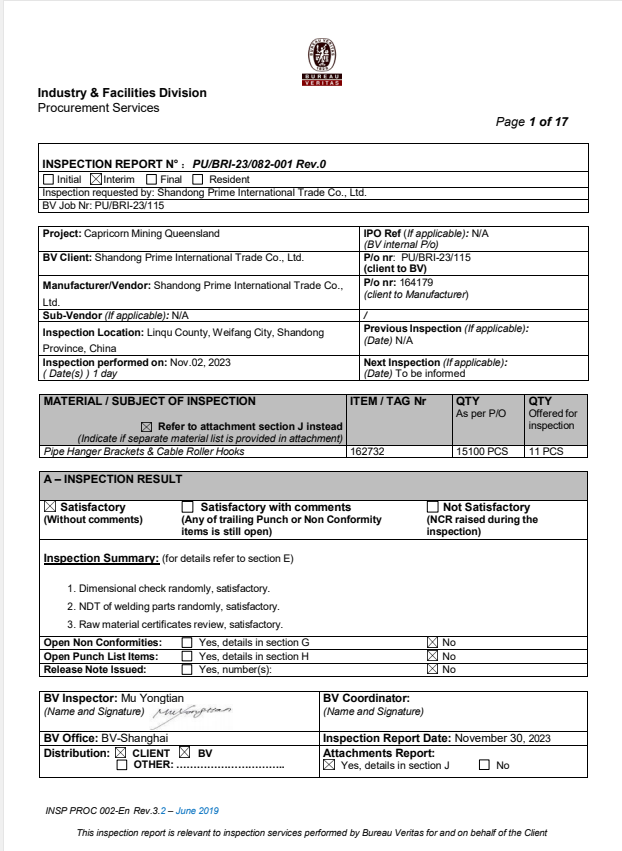

Lot Acceptance Testing

We apply statistical sampling (e.g., AQL / ISO 2859-1) to check critical dimensions, performance, and finish, ensuring consistent quality without unnecessary 100% inspection.

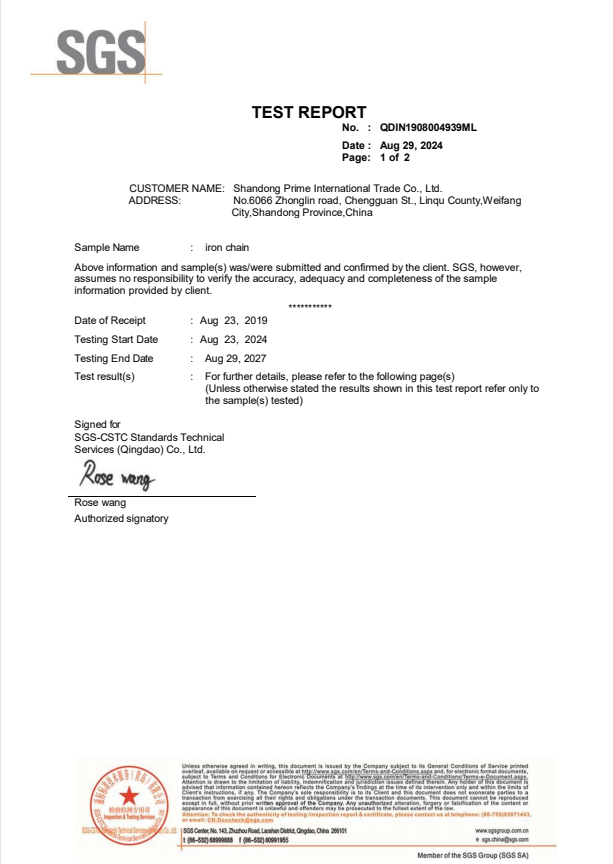

Purity Standards

We control material purity from the source (mill/resin supplier) to the finished part to ensure reliability, safety, and regulatory conformity.

Documentation Accuracy

We ensure every record—drawings, BOMs, routings, SOPs, inspection data, and shipping paperwork—matches the part, the revision, and the requirement with zero ambiguity.。

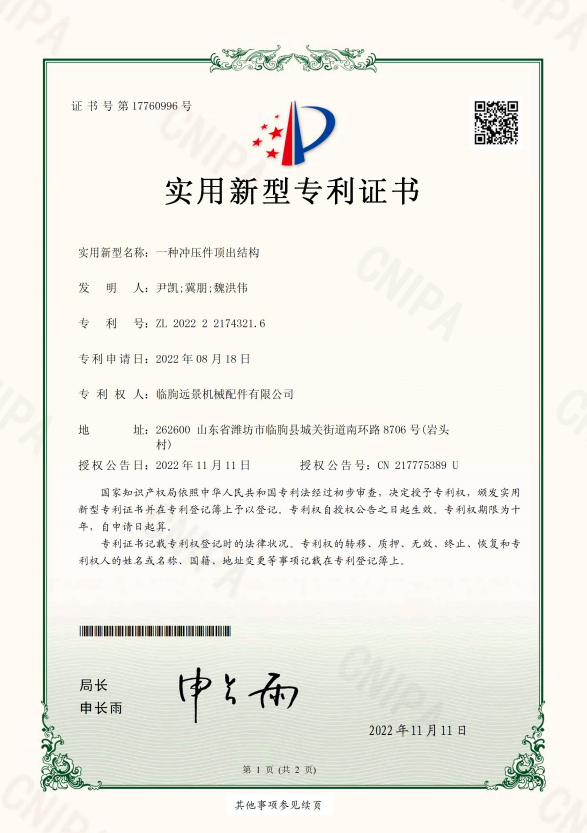

Certificates

Admiration

Maximilian

Product Manager, PM

“Die Zusammenarbeit mit Prime hat unseren Fertigungsprozess erheblich rationalisiert. Ihre Präzision und schnellen Durchlaufzeiten waren ein Schlüsselfaktor für unseren Produktionserfolg.”

Kenta Sato

Purchasing manager,UACJ

“プライムとの協力により、製造工程が大幅に合理化されました。彼らの精度と迅速な納期は、私たちの生産成功の重要な要因となっています”

Elias Söderberg

Production Supervisor,Sandvik AB

“Att arbeta med Prime har avsevärt effektiviserat vår tillverkningsprocess. Deras precision och snabba handläggningstider har varit en nyckelfaktor för vår produktionsframgång.”

Factory Insight

Our Partner ——Reliability and Cooperations

Contract US

Start the conversation

Finding top-quality custom metal parts doesn’t have to be complicated. At Prime, we guide you through it in three easy steps.

Three Decades of Trusted Production Experience, Delivered from Our Own Facilities

Custom-Designed Components Engineered for Your Specific Applications

Worldwide Delivery Network with End-to-End Logistics Services

Fast and Transparent Quotes with No Hidden Conditions

Your Designs and Information Stay Fully Confidential — Guaranteed